The Formula One chassis through the years

- Sharifah Zaqreeztrina

- Jul 30, 2025

- 4 min read

Written by Sharifah Zaqreeztrina, Edited by Marit Everett

Like any other vehicle on the road, the chassis is an essential part of a Formula One car. Also known as the ‘survival cell’, it houses all the main components and is crucial in protecting the driver’s lives.

From the series’ inception to present day, the chassis has experienced significant transformation throughout the years, taking safety and advancement of innovation into account. That evolution has led to the cars we now see on track.

1950s: Early stages

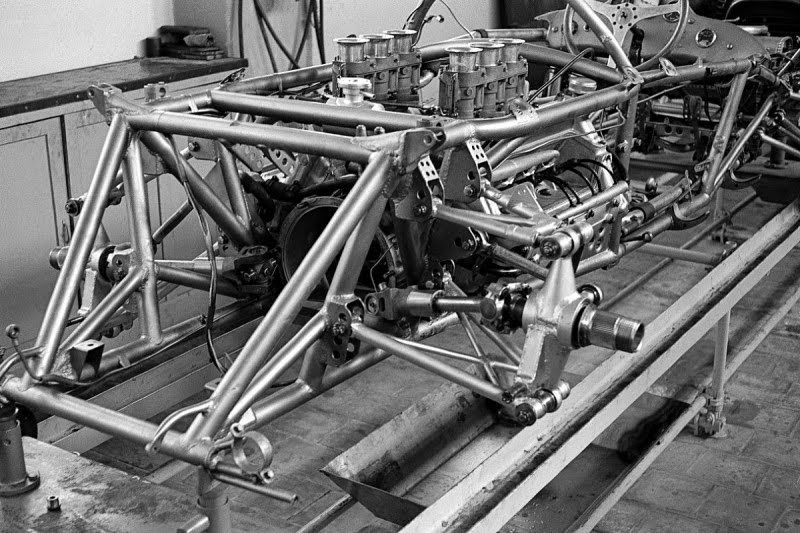

The beginning of Formula One saw small cars racing using a spaceframe design, allowing even force distribution across the chassis. The chassis was made of steel tubes welded together in three dimensions. Circular section tubes were normally used for yielding maximum strength, while the square ones were for better tube connection.

Besides its lightweight property, steel was chosen for its rigidity and strength.

As F1 was in its early stages, steel tubular chassis was a common and effective solution for car design. However, realizing how limited they are in terms of speed and safety, teams continued their search for better alternatives.

1960s: Lotus Era

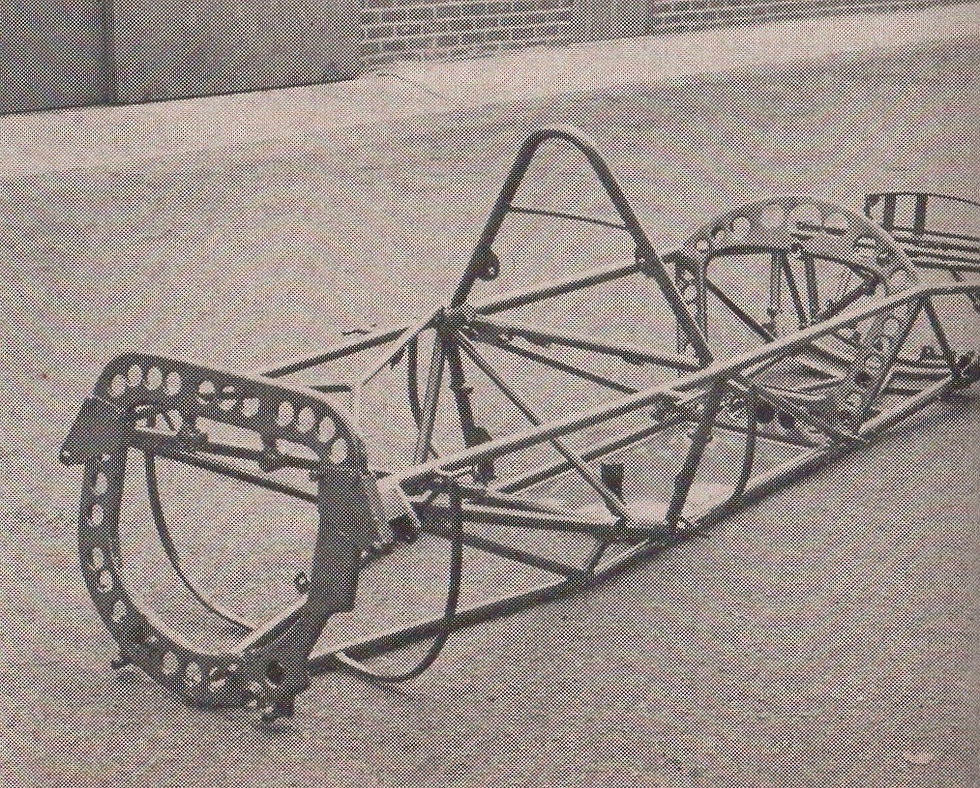

British team Lotus became the first team to replace the conventional spaceframe chassis with an aluminium sheet monocoque, implemented in the Lotus 25 of 1962.

Besides reducing the weight to half of that compared to its predecessor, the monocoque chassis provides a stronger structure to the car, making it three times stiffer. These advantages helped to improve the aerodynamic performance of the car.

A pioneering invention of lead engineer and team founder Colin Chapman, this leaped the Lotus team to success. It brought Jim Clark his two drivers’ titles in 1963 and 1965, as well as the teams’ first two constructors’ titles (‘63, ‘65) within just three seasons.

This inevitably inspired similar designs from the rest of the grid later on.

1980s: Rise of carbon fibre

Contrary to popular belief, the Lotus 88 was the first to debut an all-carbon fibre car at an F1 event. It was also another brainchild of Colin Chapman, however this time it quickly fell into the list of forbidden genius of F1 inventions.

It was banned immediately after the first practice session of the season opener at the United States Grand Prix. This was due to its twin chassis specification (one chassis staked on top of the other), as some teams found it to be violating the regulations.

McLaren then shook the racing world just a few months later. Introducing the MP4/1 in the Argentine Grand Prix, it was the first car to actually race using a full carbon fibre composite monocoque chassis.

The switch of materials was down to finding its properties no longer suitable for the car they had in mind. Aluminium was too flexible for the monocoque dimensions they measured, while steel was much heavier despite being offered more torsional stiffness (how much a material can resist when twisted).

Although that invention initially raised doubts—not many believed that this material was cut out for high-speed racing as it was generally applied in non-structural areas such as the driver’s seat and the bodywork.

However, it marked a crucial turning point in how these cars are designed. Not only is carbon fibre cheaper and five times lighter than steel, but its strength was greater than the materials previously used.

This made a huge impact on structural design, as the material made its way across all the teams over the years.

1990-present: The modern F1 chassis

From then onwards, carbon fibre remained as the ideal chassis material for every team. As the series continues to adapt to the latest resources, the chassis underwent slight adjustments to accommodate these latest technologies, such as the power units and aerodynamic devices. Safety has also become a more integral part of the design process.

For instance, the 1995 regulations saw an increase in the length of the chassis, specifically extending beyond the drivers’ feet by 50%. This is part of the safety changes done by the Fédération Internationale de l'Automobile (FIA) after its previous season. 1994 was marred by tragedies and accidents, coupled with up to 41 in-season driver changes.

Another important case of chassis optimisation occurred in 2014, where the chassis height was slashed by 16%, alongside the drastic reduction of the nose by 66%. The reduction was to prevent any car from launching upwards in case of any nose to rear tyre collisions. One notable example that drove this change was Mark Webber’s crash in Valencia in 2010.

Entering the hybrid era, these changes would also help to incorporate the hybrid power units and other systems effectively.

Despite placing more emphasis on aerodynamics, the 2022 regulations ensure more safety requirements are done for the chassis too.

In the front impact test, the chassis must absorb 48% more energy compared to the 2021 car and 15% more energy absorption in the rear. It must also withstand higher and more demanding static “squeeze” tests.

This is in a bid to ensure the drivers safety and that the chassis is homologated to race.

2026: Into the future

Formula One will soon embark on a multi-year journey under the new technical regulations, coming 2026. In the series’ effort of making a return to lighter and smaller cars, the rulebook also involves a major revamp of the chassis.

The maximum wheelbase has been shaved off by 5.6%, a similar case for the width—5%. Downforce and drag has been reduced by 30% and 55% respectively.

The progression definitely won’t stop here, as the series continues its pursuit of engineering perfection.

Comments